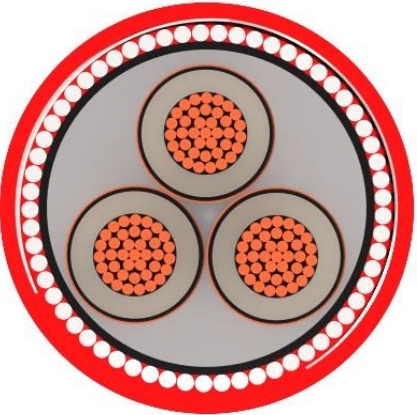

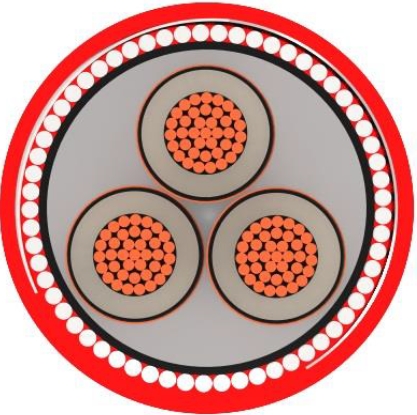

SHD-GC 15kV Triple-Core Mobile Power Cable: A Durable Solution Designed for Heavy-Duty Equipment

In harsh industrial environments, the stability and reliability of power transmission are critical. The SHD-GC 15kV triple-core mobile power cable is specifically designed to meet these demands, making it widely applicable in heavy-duty equipment across industries such as open-pit mines, mining, dredging, and tunnel boring. This cable is used in machinery like cable reelers, excavators, dredgers, and drills, and can also serve as a power feeder cable. Whether it's mining operations, tunnel construction, or dredging tasks, the SHD-GC 15kV cable ensures safe and reliable power supply for your heavy-duty equipment, safeguarding productivity and equipment integrity.

STANDARDS

ICEA S-75-381/NEMA WC 58

ASTM B 172

ASTM B 33

CAN/CSA C22.2 No. 96

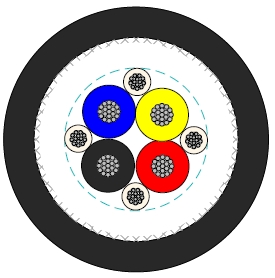

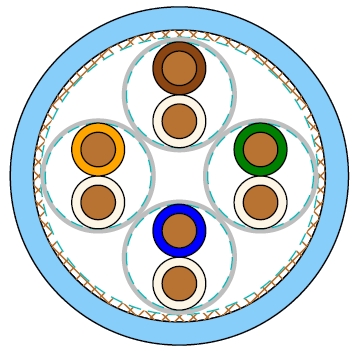

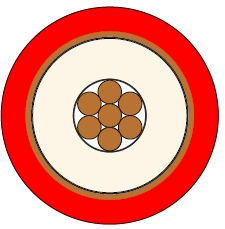

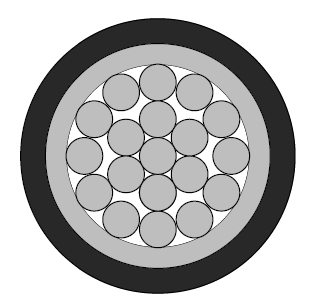

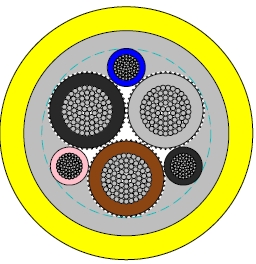

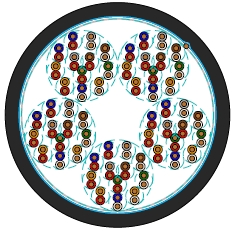

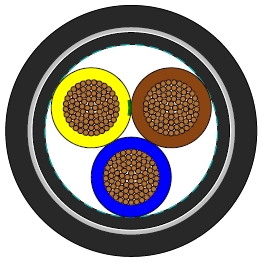

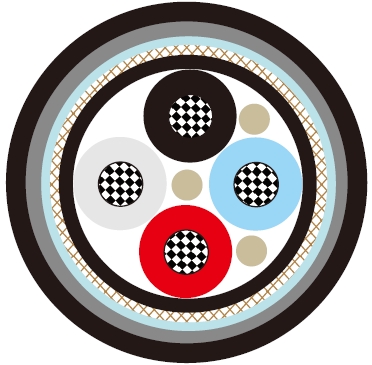

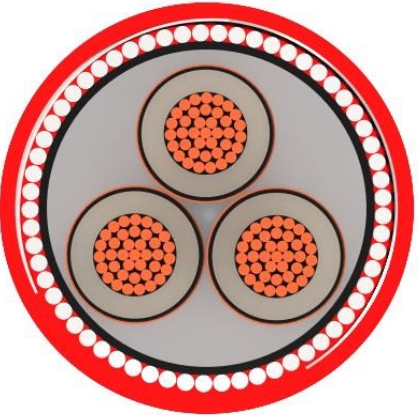

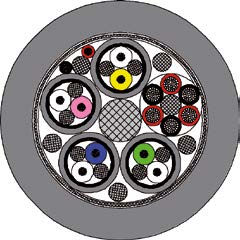

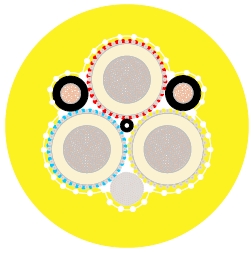

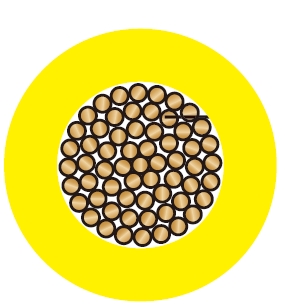

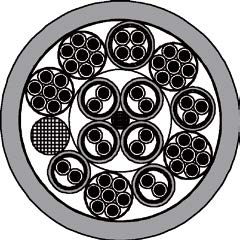

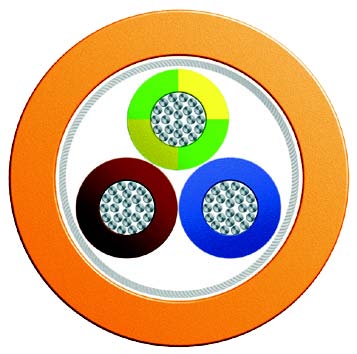

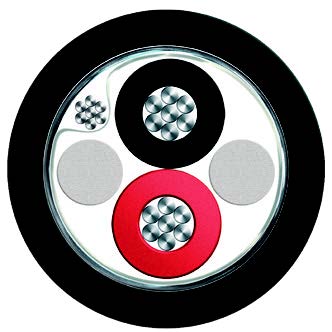

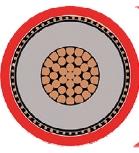

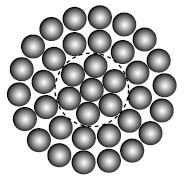

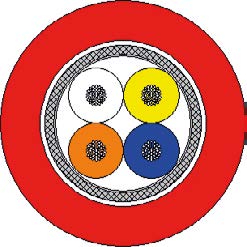

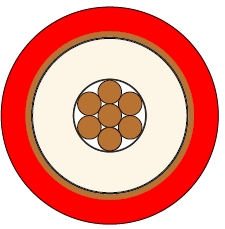

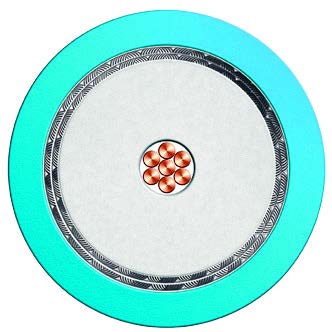

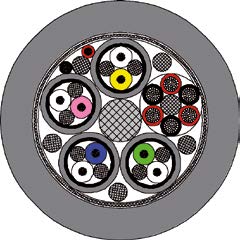

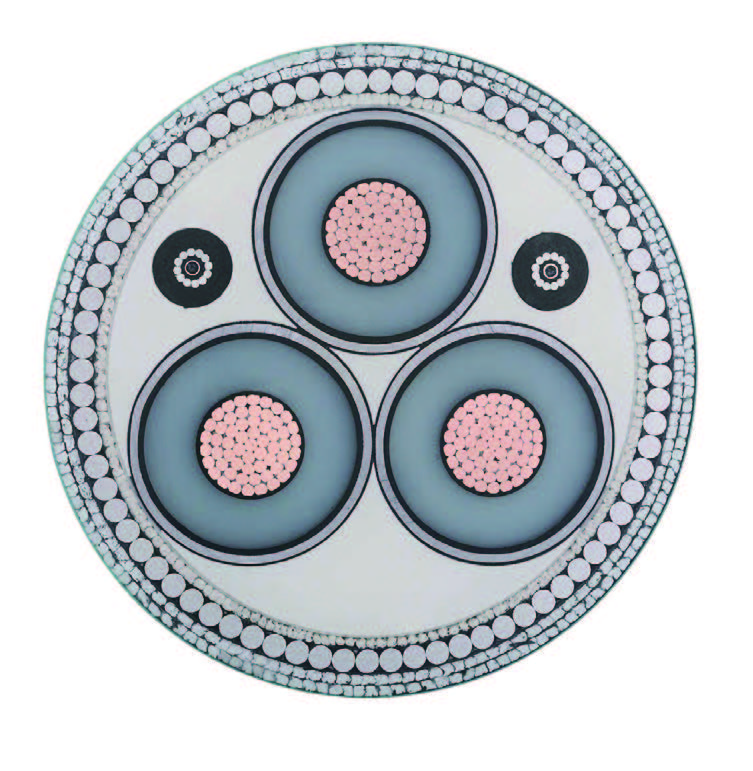

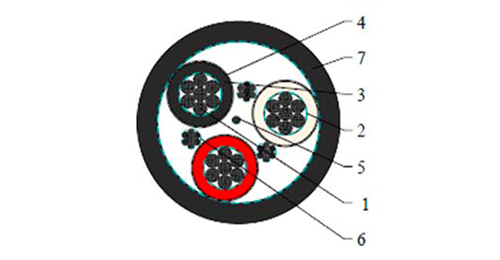

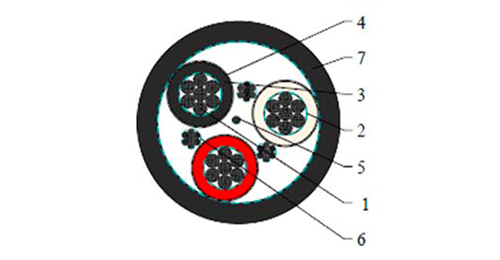

| Conductors | Stranded annealed tinned copper conductor. |

|---|---|

| Conductor Shield | Conducting layer. |

| Insulation | Ethylene Propylene Rubber (EPR). |

| Insulation Shield | Conducting tape + Tinned copper/textile braid. |

| Ground Check Conductor | Tinned copper with a yellow polypropylene insulation. |

| Grounding Conductor | Tinned copper conductor. |

| Jacket | Thermoplastic Polyurethane (TPU) Jacket, black. |

Other jacket materials such as CSP/PCP/NBR/PVC are available upon request.

Two-layer jacket with reinforcing fibre between the two layers can be offered as an option.

| Minimum Bending Radius | 8×OD |

|---|---|

| Maximum Conductor Operating Temperature | +90℃ |

| Construction | No. of Strands | Grounding Conductor Size | Ground Check Conductor Size | Nominal Insulation Thickness | Nominal Jacket Thickness | Nominal Overall Diameter Height×Width | Nominal Weight | Ampacity | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No. of cores × AWG/kcmil | - | AWG/kcmil | AWG/kcmil | inch | mm | inch | mm | inch | mm | lbs/kft | kg/km | A |

| 3×2 | 259 | 6 | 8 | 0.210 | 5.3 | 0.235 | 6.0 | 2.41 | 61.2 | 3145 | 4679 | 164 |

| 3×1 | 259 | 5 | 8 | 0.210 | 5.3 | 0.235 | 6.0 | 2.52 | 64.0 | 3567 | 5307 | 187 |

| 3×1/0 | 266 | 4 | 8 | 0.210 | 5.3 | 0.250 | 6.4 | 2.64 | 67.0 | 3976 | 5916 | 215 |

| 3×2/0 | 323 | 3 | 8 | 0.210 | 5.3 | 0.250 | 6.4 | 2.73 | 69.3 | 4526 | 6734 | 246 |

| 3×3/0 | 418 | 2 | 8 | 0.210 | 5.3 | 0.265 | 6.7 | 2.90 | 73.7 | 5231 | 7783 | 283 |

| 3×4/0 | 532 | 1 | 8 | 0.210 | 5.3 | 0.265 | 6.7 | 3.05 | 77.5 | 6033 | 8976 | 325 |

Ampacity-Based on a conductor temperature of 90℃ and an ambient air temperature of 40℃, per ICEA S-75-381